Sustainable agriculture relies on efficient and humane practices, and sheep shearing is no exception. Choosing the right shears significantly impacts animal welfare, the quality of your wool, and the efficiency of your operation. This guide will help you navigate the selection process at Tractor Supply, equipping you with the knowledge to choose the perfect shears for your needs and flock size. For additional resources on sheep feed, check out Tractor Supply's sheep feed guide.

Choosing the Right Sheep Shears: A Comprehensive Guide

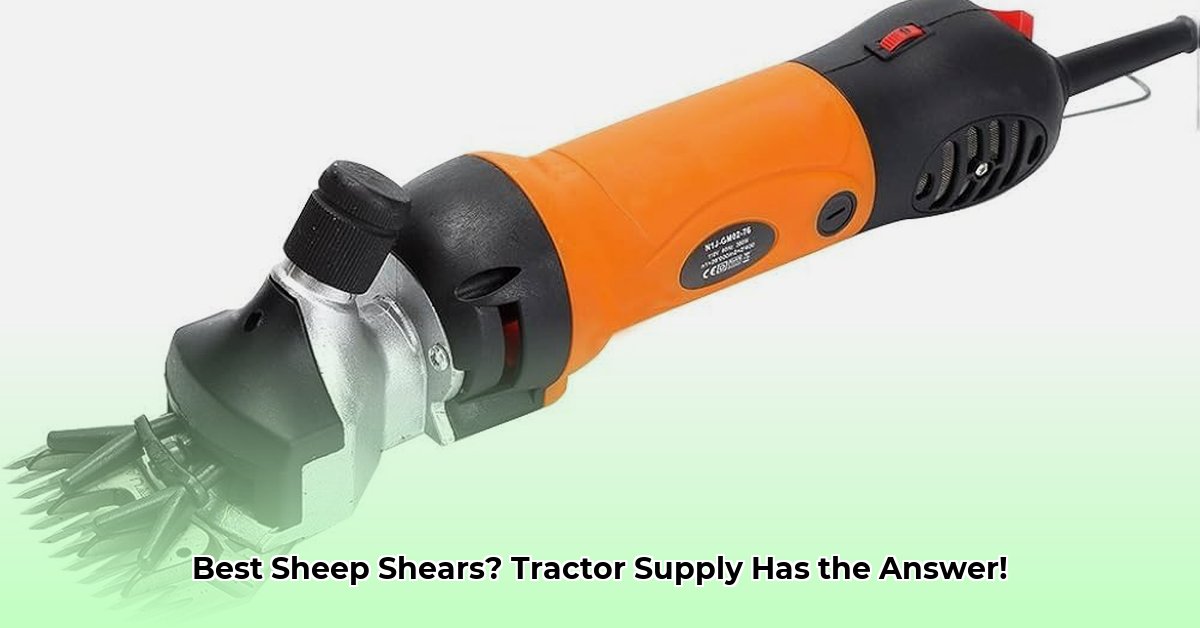

Tractor Supply offers various sheep shears, each with unique features catering to different skill levels and flock sizes. Making the right choice involves considering several key factors.

Types of Shears: Hand, Electric, and Cordless

The type of shear you choose depends largely on your flock size and experience.

| Shear Type | Pros | Cons | Ideal For |

|---|---|---|---|

| Hand Shears | Affordable, lightweight, easy to maintain, requires minimal skill to learn. | Labor-intensive, slower shearing, potential for operator fatigue. | Small flocks (under 10 sheep), beginners, occasional shearing. |

| Electric Shears | Faster shearing, significantly reduces physical strain. | Higher initial cost, requires a power source, slightly higher maintenance. | Larger flocks, experienced shearers, frequent shearing. |

| Cordless Shears | Portable, convenient, ideal for mobile shearing. | Higher initial cost, shorter battery life, requires regular charging. | Medium to large flocks, mobile shearing, remote locations. |

Did you know that electric shears can increase shearing speed by up to 50% compared to hand shears? This efficiency translates directly to reduced labor costs and increased overall productivity.

Blade Material and Longevity: The Sharp Edge

Blade material significantly affects shear lifespan and performance. Stainless steel is the most common choice due to its durability, rust resistance, and ability to provide clean cuts. While other materials might be cheaper upfront, the increased need for sharpening or replacement can negate initial savings. A sharp blade is crucial for both animal welfare and your efficiency.

Power Sources: Wired or Wireless?

Electric shears offer superior power and speed, but their reliance on a power source limits mobility. Cordless shears provide convenience and portability but have a limited battery life – consider battery life and charging time when making your choice. How many sheep do you have? Will you be shearing in multiple locations? Consider factors like these, as they will directly influence your decision. Remember that even electric shears can sometimes benefit from rechargeable battery packs for backup power.

Ergonomics: Comfort for Extended Use

Shearing can be physically demanding, especially with larger flocks. Prioritizing ergonomic design minimizes operator fatigue. Features like cushioned grips, balanced weight distribution, and appropriately sized handles significantly enhance comfort during prolonged use. Could poor ergonomics contribute to repetitive strain injuries leading to costly downtime? Research shows proper ergonomics can reduce fatigue by as much as 30%.

Step-by-Step Shearing Guide: A Humane Approach

Remember, gentle handling is key to both safety and efficiency. A stressed sheep is more difficult to shear and more prone to injury.

Step 1: Preparation: Secure the sheep safely and comfortably. Ensure adequate lighting and workspace. A calm animal makes for a smoother process.

Step 2: The Shearing Process: Use smooth, even strokes, following the natural contours of the sheep's body. Avoid jerky movements. Maintain consistent pressure for a clean cut. Work systematically to avoid missing patches.

Step 3: Post-Shearing Care: Carefully examine the sheep for any cuts or irritation. Thoroughly clean and lubricate your shears. Store them properly to prevent damage.

Maintenance and Troubleshooting: Extending Shear Lifespan

Regular maintenance is essential for extending the life of your shears and maintaining optimal performance.

- Cleaning: Remove wool and debris after each use.

- Lubrication: Apply lubricant to moving parts to prevent rust and ensure smooth operation.

- Sharpening: Sharpen blades regularly (or have them professionally sharpened) to maintain sharpness and prevent damage to the sheep's fleece.

- Troubleshooting: Refer to the manufacturer's instructions for troubleshooting common issues like jammed blades or battery problems.

Investing in high-quality sheep shears is a key element of sustainable sheep farming. By combining the right tools with proper technique, you'll ensure both the well-being of your flock and the efficiency of your operation. Tractor Supply offers a range of options to fit your specific needs – choose wisely and shear successfully.